Introduction

Yield strength is an important specification in material science. It is mainly used in manufacturing processes of materials such as forging, compressing, and rolling. When designing a material or components, material engineers should be aware of yield strength as it depicts the maximum load limit of the material.

Yield Strength

The yield strength in a material is defined as the maximum strength or stress that has been developed in that material without plastic deformation. It is commonly a stress point that provides an approximate elastic limit when the material is completely deformed. The unit of yield strength is pascals (N/m2). For example, in construction works, the buildings should possess the maximum load limit when it is exposed to higher loads like earthquakes.

The elastic deformation will happen before the material reaches the stress point. But when the applied stress is removed, the material will come back to its original form. The permanent deformation happens when the stress point is reached. This change in shape is irreversible.

Determination of Yield Strength

The divider method is used to determine the yield strength. In this method, an observer uses a pair of dividers to watch the elongation in the specimens. The specimens have 2 standard marks in them. The load is recorded when a visible stretch is made between the marks. The maximum stress point is derived from the recorded load. This is the practical proof test that determines yield strength with the help of load.

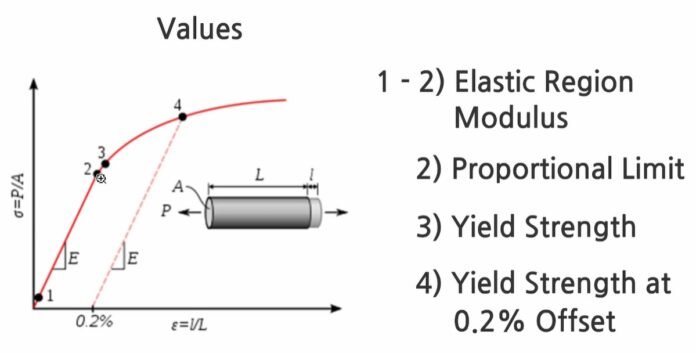

The yield strength can typically be calculated by a tensile test with the help of a stress-strain curve.

Illustration

Let’s take the example of soft steel. When the soft steel is treated with excessive tension, it shows the value of the yield point. As a result of this, the load gets reduced and strain will increase. Simultaneously, plastic deformation will happen and a stress-strain curve can be plotted.

The maximum yield point is the high-stress point on the curve and the minimum yield point occurs at the low-stress point. The soft steel elongates further. Then, the plastic strains evolve that become thin in some areas. This forms a depression on the surface called worms or stretcher strains. In the stress-strain curve, two limits can be noted:

- Proportional limit

- Elastic limit

Proportional limit

The proportional limit in the curve is the limit of points that emerges from the straight line. Here, the soft steel supports Hooke’s law. Hooke’s law states that stress is proportional to strain. Hence, in soft steel, the stress is proportional to strain.

Elastic limit

The elastic limit is the limit that occurs at the beginning of plastic deformation and is not determined from the curve. It is determined by the intervention of loading and unloading. Here, the loading happens gradually and complete plastic deformation is detected. It is considered a permanent set and elastic limits are described as a qualitative term.

Yield Strength Formula

The yield strength can be directly determined through a stress-strain curve or by calculating the intersection point and 0.2% line offset rule in the stress-strain curve, as below

ε = 0.002 * E

where ε = yield strength/stress

E = Young modulus of the material in which the ratio between strain and stress is constant.

The above expression can be used in single-axis applications and is called a yield strength formula.

Yield Strength Anomaly

Yield strength is directly proportional to the rate of strain and indirectly proportional to temperature. The materials which possess the characteristics of yield strength are mainly used in applications where high strength is incurred at maximum temperature. This is known as yield strength anomaly or yield stress anomaly. Determining yield strength is difficult without the intervention of load, stress, and strain.

Difference Between Tensile Strength and Yield Strength

The maximum strength that a material can withstand before failing is called tensile strength whereas the maximum stress at which the material can sustain its deforming properties is known as yield strength. In the stress-strain curve, the area below the tensile loading curve shows the ultimate tensile strength. Under that curve, the higher stress point which intersects with the yield point depicts the yield strength.

Recommended Articles:

Youngs Modulus Elastic Modulus

Brief Introduction of Zener Diode

Important notes on Derivation of Bulk modulus

Thin Lens Formula for Concave and Convex Lens

The Gold Mine of Physics: Deriving Important Physics Formulas

Formula for yield strength ε= 0.002 * E where ε = yield strength E = Young modulus of the material The above expression is called the yield strength formula. The proportional limit in the curve is the limit of points that emerges from the straight line. The elastic limit is the quantitative term that occurs at the beginning of plastic deformation and is not determined from the curve. It is determined by the intervention of loading and unloading. Yield strength is directly proportional to the rate of strain and indirectly proportional to temperature. The materials which possess the characteristics of yield strength are mainly used in applications where high strength is incurred at maximum temperature. This is known as yield strength anomaly or yield stress anomaly. Yield strength can be determined by divider methods or tensile tests. In a tensile test, the stress-strain curve is plotted and yield strength is directly determined from it. It is also determined by calculating the intersection point and 0.2% line offset in the stress-strain curve. Yield strength The maximum stress at which the material can sustain its deforming properties is known as yield strength. Yield strength FAQs

What is the yield strength formula?

Yield strength can be directly determined by calculating the intersection point and 0.2% line offset in the stress-strain curve. What is the difference between proportional and elastic limits?

What is the yield stress anomaly?

How can yield strength be determined?

Define yield strength.