Introduction

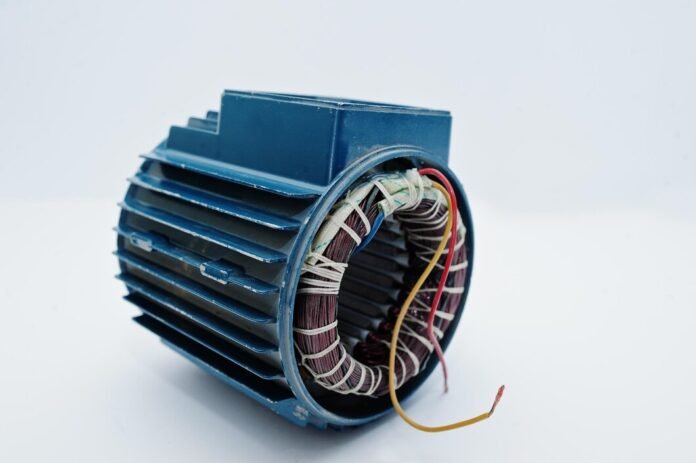

We know that there are two different motors: AC and DC. The AC motor converts electrical energy into mechanical energy by using AC. The varieties of AC motors are numerous. The DC motor converts electrical energy into mechanical energy using DC. The key benefits of adopting this are that we can adjust the speed and that all takes up less room. A permanent magnet DC motor uses permanent magnets to produce the field flux. The other three types were categorised depending on the electrical connections between the stator and the rotor. They each have a particular torque and speed.

Types of DC Motors

1. DC Series Motors

Field windings and armature are linked together in a DC series motor. A relatively small group of turns of bigger wire or copper strips in the series winding carries the load current of the motor. Due to the low resistance of the windings, a considerable current could be pulled during start-up, resulting in a high beginning torque. It is advantageous for heavy applications with high beginning loads, tractors, cranes, and other heavy equipment. A series motor’s speed is load-dependent, so when the circuit’s full load current has decreased, the speed increase.

2. DC Shunt Motors

The field winding and armature are parallelly connected (shunted) in a DC Shunt motor. Because the shunt winding runs across the DC field supply, its field current would be constant. It is tightly closed by numerous turns of small copper wire. The motor will operate at its maximum rate, and a change in load won’t significantly slow it down. A constant-speed shunt motor would be preferred for the application, even if the beginning torque would be lower than a similar-sized series motor.

3. DC Compound Motors

Most of the field in such a DC compound motor is wound as just a shunt field, containing a few turns of series winding on top. It linked the series turns with the armature and the shunt across the field supply. As a result, the traits of a shunt and series motor are combined. Although it won’t be as high as a series motor, the starting torque will be more than a shunt motor. Depending on the percentage of area space allotted to the series winding, the speed will alter with the load. Set up the series field so that speed changes depending on the load.

Uses of DC Motors

DC motors are used in various applications because these offer a higher starting torque than induction motors. Some of the applications for DC motors are described in the following list.

1. Cranes

The motor must sustain a full load at zero speed in an application involving overhauling loads since mechanical brakes might not be necessary. DC motors are the most economical and secure choice in those scenarios. They are quite useful because of their size and weight.

2. Diesel-Electric Locomotives

In a diesel-electric locomotive, the combustion produced by the diesel engine is paired with a generator that transforms it from rotational energy to electrical energy. The engine’s wheels are connected to DC motors which receive the transformed electrical energy.

3. Ceiling Fans

DC-powered ceiling fans have grown incredibly popular. They have a quick start-up torque and require less electricity. A transformer may quickly convert the alternating current in a house or office to a direct current, reducing the fan’s power. Brushless DC motors are most frequently utilised in ceiling fans, much like in other DC motor applications.

Recommended Articles:

Types of Forces

Types of Friction

Electrical Generators and Their Types

Types of Levers – Basic Definitions and Examples

Differences Types of Motors

DC motors have three primary varieties: series, shunt, and compound. These words describe how the field windings are connected to the armature circuit. For applications requiring high starter torque without the requirement for speed adjustment, series-wound DC motors work well. Similarly to a shunt motor, a DC series motor slows down as a load is applied, reducing the back EMF and increasing the net voltage. Permanent magnets are included in the stator of a permanent magnet brush DC motor, so an external field current is not required. This design is popular in low-power applications up to roughly 2 HP and is smaller, lighter, and much more energy-efficient than other brush DC motor types. An electrical motor that transforms direct current electrical energy into mechanical energy is known as a DC motor. We can infer from the definition just above that a DC motor is any electric motor which runs on direct current or DC. A DC motor is an electrical device that transforms electrical energy into mechanical energy. Direct current, the electrical energy used as an input source in a DC motor, is turned into mechanical rotation. Vegetables Names FAQs

What are the different types of DC motors?

Which DC motor type is best?

Which DC motor has the best performance?

What is a DC motor?

How does a DC motor operate?