Introduction

Compressive stress is a type of mechanical stress that occurs when an external force is applied to an object, causing it to be compressed or shortened along its axis. This type of stress can occur in many different materials, including metals, ceramics, and polymers, and can have a significant impact on their properties and performance.

Compressive stress is typically measured in units of pressure, such as pounds per square inch (psi) or newtons per square meter (N/m²). The amount of compressive stress that a material can withstand before it fails is known as its compressive strength, and this value can vary widely depending on the type and quality of the material.

One common application of compressive stress is in the design and construction of structural components, such as columns, beams, and walls. These components are often subjected to significant compressive forces, either due to the weight of the structure above them or as a result of external loads, such as wind or seismic activity.

In these applications, it is important to ensure that the compressive strength of the materials used is sufficient to withstand the anticipated loads and stresses over the life of the structure. This may involve careful selection of materials, such as high-strength concrete or steel, or the use of reinforcement techniques, such as adding steel bars or mesh to concrete.

Another important consideration when dealing with compressive stress is the phenomenon of buckling. Buckling occurs when an object is subjected to compressive stress that exceeds its critical buckling load, causing it to suddenly collapse or buckle. This can be a significant concern in the design of long, slender structures, such as columns or beams, where buckling can occur even when the compressive stress is well below the material’s ultimate strength.

In addition to structural applications, compressive stress can also be used in various manufacturing processes, such as forging and extrusion. In these processes, a compressive force is applied to a material to shape it or change its physical properties. For example, forging involves applying a compressive force to a metal workpiece to shape it into a desired form, while extrusion involves forcing a material, such as plastic or metal, through a die to produce a specific shape or profile.

Overall, compressive stress is a fundamental concept in materials science and engineering, with important implications for the design and performance of structures, components, and manufacturing processes. By understanding the properties and behavior of materials under compressive stress, engineers and designers can create safer, more reliable, and more efficient structures and products.

Unit and formula of Compressive Stress

Compressive stress is the stress that occurs when a material is subjected to a force that compresses or squeezes it, resulting in a decrease in its volume. The unit of compressive stress is the same as that of all other types of stress: force per unit area, or pressure. The Pascal (Pa), which is equal to one Newton of force per square metre of area, is the SI unit for pressure.

Therefore, the formula for compressive stress is:

Compressive Stress = Force / Area

where force is the compressive force applied to the material and area is the cross-sectional area of the material that is perpendicular to the direction of the applied force.

In engineering and physics, compressive stress is an important concept, as it is encountered in many structures and materials, such as buildings, bridges, and mechanical components.

Dimension of Compressive Stress

The dimension of compressive stress is typically expressed in units of pressure, such as pounds per square inch (psi) or pascals (Pa). In the United States, psi is commonly used, while the metric system uses Pa.

The formula for compressive stress is:

σ = F/A

Where σ is the compressive stress, F is the compressive force, and A is the cross-sectional area of the object being compressed. This formula shows that compressive stress is directly proportional to the force applied and inversely proportional to the cross-sectional area.

The dimension of compressive stress can also be expressed in terms of strain, which is the ratio of the change in length of an object to its original length. The relationship between stress and strain is described by the stress-strain curve, which is specific to the material being compressed.

What is Compressive Strength?

Compressive strength refers to the ability of a material to withstand forces that compress or squeeze it. This force is usually applied perpendicular to the surface of the material, causing it to deform and potentially fail. The compressive strength of a material is a fundamental property that determines its ability to resist deformation under compressive loads. It is an essential property in engineering design and material selection, as it can help predict the behavior and durability of structures and components.

The compressive strength of a material is typically measured by subjecting a sample of the material to a gradually increasing load until it fails or fractures. The maximum load that the material can withstand before failing is recorded as its compressive strength. The compressive strength is expressed in units of force per unit area, such as pounds per square inch (psi) or megapascals (MPa).

The compressive strength of a material can be influenced by various factors, including its composition, microstructure, porosity, and processing history. For example, materials with a higher density, more uniform microstructure, and fewer defects tend to have higher compressive strengths. Materials that are more brittle, such as ceramics, may have higher compressive strengths than ductile materials, such as metals, which are more prone to plastic deformation under compressive loads.

The compressive strength of a material can also depend on the direction of the applied force relative to the orientation of the material’s grains or fibers. Anisotropic materials, such as wood or composite materials, may have different compressive strengths in different directions. It is important to consider the orientation of the material when designing structures or components that will be subjected to compressive loads.

Compressive strength is a crucial property of materials that is essential for engineering design and material selection. It is determined by the material’s ability to resist deformation under compressive loads and is influenced by factors such as composition, microstructure, and processing history.

Difference between Tensile Stress and Compressive Stress

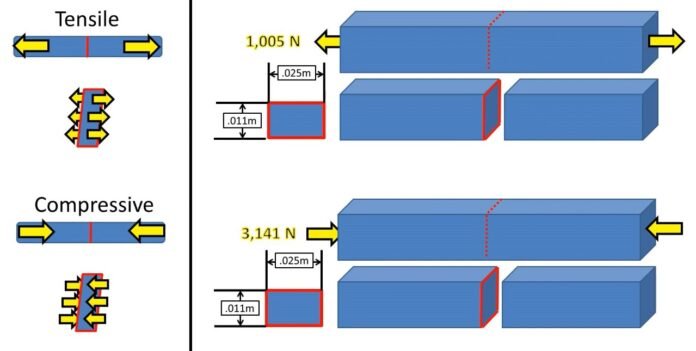

Tensile stress and compressive stress are two types of mechanical stresses that act on materials in opposite directions. Tensile stress is a stress that occurs when a material is subjected to a pulling or stretching force, whereas compressive stress is a stress that occurs when a material is subjected to a squeezing or compressing force.

Tensile stress tends to elongate or stretch the material, while compressive stress tends to shorten or compress it. The magnitude of tensile stress is measured as the force per unit area, while the magnitude of compressive stress is measured in the same way, but with the force applied in the opposite direction.

One of the main differences between tensile stress and compressive stress is that tensile stress can cause a material to break apart, while compressive stress can cause it to buckle or collapse. This is because materials are typically stronger in compression than they are in tension.

Another difference is that tensile stress tends to occur in structures that are being pulled or stretched, such as cables, while compressive stress tends to occur in structures that are being pushed or compressed, such as columns or beams.

Overall, tensile stress and compressive stress are two important concepts in the field of materials science and engineering. Understanding their differences is essential for designing and analyzing structures that are subjected to various types of mechanical loading.

Recommended Articles:

Coefficient of Linear Expansion: Expansion, Materials, and Examples

Coherent Sources: Production, Examples, Need and Characteristics

Color of Sunlight: Introduction, Factors, Colors and Effects

Communication Systems: Introduction, Types, Examples And Elements

Compound Lenses Thin Lenses in Contact

Compressive stress is a type of stress that occurs when an object is being pushed or compressed in a perpendicular direction to its surface. Examples of compressive stress include the weight of a heavy object pushing down on a surface, the force of a hydraulic press compressing a material, or the weight of a person standing on the ground. Compressive stress is typically measured in units of force per unit area, such as pounds per square inch (psi) or newtons per square meter (N/m²). The material will experience a decrease in volume and an increase in density as it is compressed. If the compressive stress is too high, the material may undergo plastic deformation or fracture. Tensile stress is a type of stress that occurs when an object is being stretched or pulled in a perpendicular direction to its surface, while compressive stress occurs when an object is being pushed or compressed in a perpendicular direction to its surface. Compressive stress is used in a variety of applications, such as in the construction of buildings and bridges, the manufacturing of industrial equipment, and the design of automotive and aerospace components. It is also used in the processing of materials such as plastics and metals. Compressive Stress FAQs

What is compressive stress?

What are some examples of compressive stress?

How is compressive stress measured?

What happens to a material under compressive stress?

How does compressive stress differ from tensile stress?

What are some common applications of compressive stress?