The electronic resistor was invented by NIHF Inductee Otis Boykin. A resistor is a passive electrical component with two terminals and is a fundamental device used in all electronics for restricting the flow of electric current in the circuit. To make the resistance, different alloys and metals are used, like platinum, nichrome, brass, and tungsten. Resistors are used in electronic circuits to adjust signal levels, cut down on current flow, bias active elements, divide voltages, and end transmission lines, among other things. Carbon resistors have a wide range of values and great stability and hence they are one of the most commonly used types of resistors in electronics today.

What are Carbon Resistors?

Carbon resistors are one of several types of resistors like Metal Film Resistors, Wire wound Resistors, Metal Oxide Resistors, and Metal Strip Resistors. These are made with a thin film of carbon black and graphite powder between two metal plates. These resistors come in different sizes with power dissipation limits, commonly from 1 watt down to 0.125 i.e., 1/8 watt. To make the resistance, a variety of metals and alloys are utilized like platinum, nichrome, brass, and tungsten. However, most of these metals when compared to carbon resistors, have low electrical resistance since it is very difficult to create high resistance without making the resistor bulky. Resistance is known to be directly proportional to the product of the resistivity and the resistor’s length.

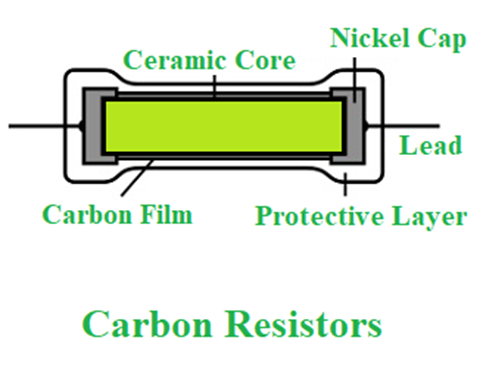

Components of Carbon Resistors

Though carbon resistors can be constructed from a variety of materials, some essential parts are mentioned below:

Carbon Film: Carbon film resistors are made with deposition and have a thin layer of metal on top. Use: This material is designed to handle high temperatures and voltages without breaking down over time.

Lead: The leads are used to connect a carbon resistor to other components in an electrical circuit and Carbon resistors can be made with or without lead, depending on their design and application requirements.

Use: Carbon resistors with leaded ends are typically used for high-power applications such as motor control circuits and power supplies.

Ceramic Core: In a carbon resistor, there are two insulating layers on each side of a wire coil.

Use: It acts as a bridge for conducting electricity from one end to another end and also helps in reducing heat loss in resistors.

Protective Lacquer: Protective Lacquer is a lacquer that is applied to carbon resistors to prevent them from oxidation.

Use: This is applied so that carbon resistors do not react with oxygen or moisture in their environment.

Nickel Cap: Carbon-Film resistors are made with a cap of nickel that is baked onto their surface.

Use: This cap helps to protect against oxidation and degradation over time and these resistors offer very high precision at an economical price.

Symbol of a carbon resistor

In most of the electronic and electrical circuit diagrams, the most used symbol is that of a zig-zag line for a resistor with the value of its resistance denoted by the Ohms. Fixed resistors typically have only one value of the resistance. Still, variable resistors can be provided with resistances of an infinite number, which may vary from zero to their maximum value.

The notation used for Carbon resistors is “CR” (CR10kΩ) and is available in:

E6(+20% tolerance(accuracy),

E12(+10% tolerance)

E24(+5% tolerance).

Working of Carbon resistors

While building an electronic or electric circuit for a certain purpose, the exact amount of resistance must be induced in the circuit board. It is accomplished by using carbon resistors, which are small packet of resistance that is connected to the circuit to limit the flow of current by a specific amount.

Carbon is deposited onto a ceramic core and the deposited carbon is etched in a spiral, which transforms it into a wire coiled on a ceramic core. The diameter, pitch, and length of the carbon spiral vary depending on the resistance required by us. Nickel caps are connected to both ends of the core to ensure that the lead and carbon make excellent contact.

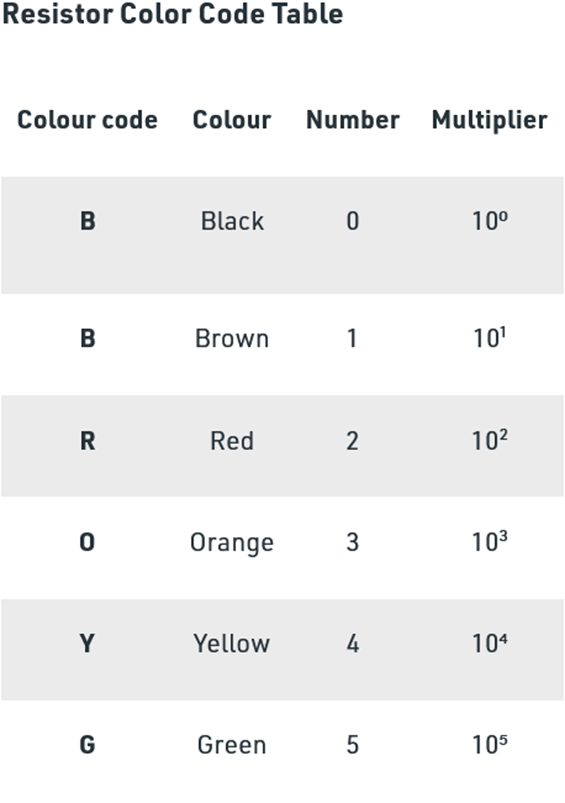

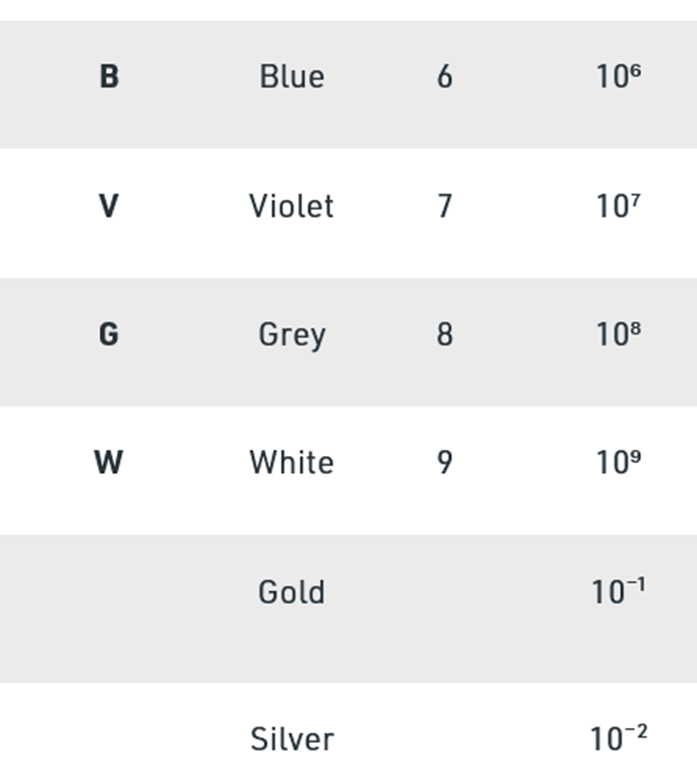

Resistor Colour Code

It is challenging to print resistance values on the resistors because of the small size of carbon resistors and to solve this problem the resistor color code was invented by the Radio Manufacturers Association (RMA) in the 1920s.

Any leaded resistors with a power rating of less than one watt can be identified by the color bands. They are specified by a number of bands, which collectively determine the tolerance rate, resistance value, and, in some cases, dependability and failure rates.

Resistor color code Table:

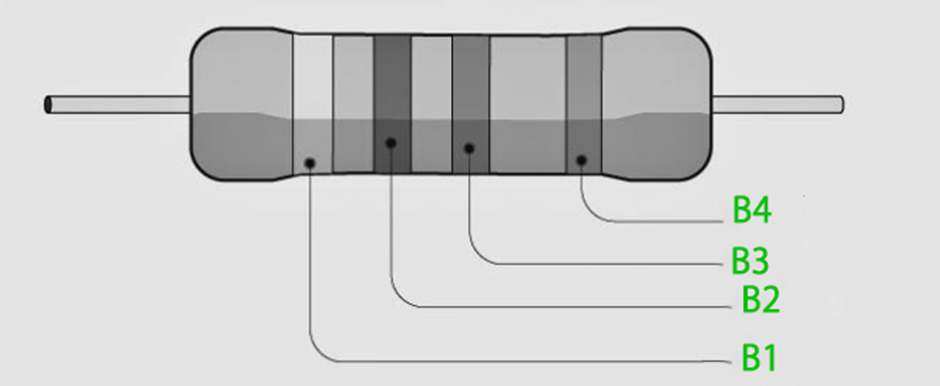

To read get the resistance of the resistor one should hold the resistor in such a way that the bands are clearly visible. There are four bands from which we can calculate the resistance of the resistor

B1: Indicates 1st significant figure

B2: Indicates 2nd significant figure

B3: Indicates multiple of 10

B4: Shows tolerance ( % error in the result)

The fourth band i.e., B4 is generally placed a little further away from the other bands.

Applications of Carbon Resistors

Carbon resistors are used when high precision and very high power are required and, in these cases, no semiconductor device can be used. These have characteristics intermediate between metal-wire resistors and carbon composition resistors. They have a very high level of electrical resistance when they’re in their operating range and this quality makes them useful for protecting circuits from electric shorts and surges.

Some major applications are:

Because of the carbon resistor’s ability to endure high energy pulses despite its small size, it may be employed in a variety of applications in our day-to-day life.

The power supply of radar systems, X- rays, and lasers all use a carbon resistor.

In an AC power supply circuit, carbon resistors are used to limit current and regulate voltage while in a DC power supply circuit, carbon resistors are used to adjust the voltage.

A carbon resistor is used in many other circuits such as lamp dimmer circuits and motor speed control etc.

It is also utilized in delicate patient-attached measuring equipment and medical defibrillators that have to be shielded from high-energy pulses.

Advantages

Carbon resistors are inexpensive to manufacture, compact and can be directly printed onto circuit boards (like the computer processors in tablets and phones). They also reproduce resistance fairly well within practical requirements as compared to metal wires, which are expensive to produce while carbon is abundantly available, making it cheap.

The Carbon resistor’s ability to tolerate high-energy pulses makes it more important.

Disadvantages

If these resistors are kept for a long time, due to aging the resistance values may change.

They are not capable of handling atmospheric moisture, humidity, and high temperature.

Difference between Metal film resistors and Carbon resistors

Metal film resistors have a very thin metal film (tin, antimony, nickel-chromium alloy, etc.) on ceramic while Carbon film resistors have a thin layer of carbon from pure graphite on ceramic. The accuracy of metal film resistors is much higher than that of carbon film resistors. Metal oxide film resistors can operate in a wide range of resistors and can withstand a higher temperature than carbon film resistors. In contrast to carbon film resistors, metal oxide film resistors have a low noise design and they keep the minimum current.

Recommended Articles:

Buoyant Force: Introduction, Demonstration an Applications

CALORIMETER: PRINCIPLE, TYPES & APPLICATIONS

Capacitor And Capacitance: Introduction, Work, Value and Units

CAPACITOR TYPES: Classification, Types, Application, Factor, Common and Value

Capacitors in Parallel: Introduction, Applications, and Combination

The electronic resistor was invented by NIHF Inductee Otis Boykin. Metal oxide film resistors can operate in a wide range of resistors and can withstand a higher temperature than carbon film resistors. In an AC power supply circuit, carbon resistors are used to limit current and regulate voltage while in a DC power supply circuit, carbon resistors are used to adjust the voltage. A carbon resistor is used in many other circuits such as lamp dimmer circuits and motor speed control etc. Nickel cap, carbon film, lead, ceramic core, and protective lacquer. Carbon Resistors FAQs

Who invented resistors?

State any one difference between a metal film resistor and a carbon film resistor.

State any two applications of Carbon resistors.

Enlist the components of Carbon resistors.