Introduction

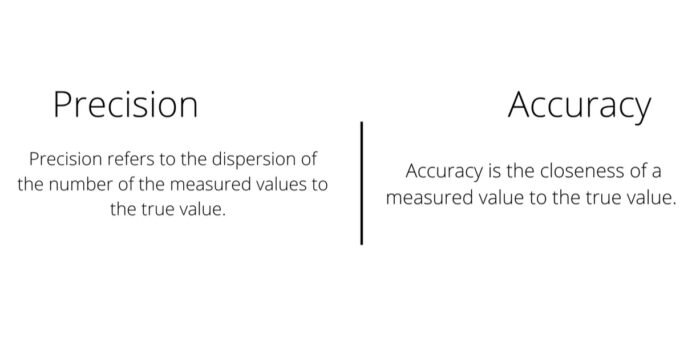

ARecommended Articles:ccuracy, precision, and error measurement are three concepts that are commonly used in various fields, such as science, engineering, and statistics. These concepts are important because they help us to understand the quality and reliability of measurements, data, and experiments. Accuracy refers to how close a measurement is to the true value or target. Precision refers to how reproducible or consistent a set of measurements is. Error measurement refers to the difference between a measured value and the true value or target.

Accuracy

Accuracy is a measurement of how close a result is to the true value. It’s important because it helps us determine how reliable measurement is. There are several methods used to measure accuracy, including comparing the measurement to a known standard or repeating the measurement multiple times and taking the average.

However, several sources of error can impact accuracy. For example, the measuring equipment used may not be calibrated correctly, or there may be human error in taking the measurement. To improve accuracy, it’s important to identify and minimize these sources of error.

For instance, imagine you need to measure the weight of a bag of sugar. If the true weight is 1 kilogram, but your measurement is 0.9 kilograms, then your accuracy is low. However, if you repeat the measurement multiple times and gain an average weight of 0.95 kilograms, then your accuracy has improved.

Precision

Precision is a measure of the consistency or reproducibility of a set of measurements. It describes how closely the individual measurements in a set match each other.

For example, imagine you are measuring the length of a pencil. If you measure it ten times and get results that are all very similar, then you have high precision. However, if you get different results each time you measure, then you have low precision.

There are several methods used to measure precision, including standard deviation and coefficient of variation.

- Standard deviation is a measure of how spread out the data is from the mean value

- The coefficient of variation is the ratio of the standard deviation to the mean. A low coefficient of variation indicates a high level of precision.

However, several sources of error can impact precision, including systematic errors and random errors.

- Systematic errors occur when there is a consistent bias or offset in the measurements.

- Random errors, on the other hand, are caused by fluctuations in the measurement process and cannot be eliminated.

To improve precision, it’s important to identify and minimize sources of error. This can be done through careful experimental design, using calibrated instruments, and taking repeated measurements.

Error measurement

Error measurement refers to the difference between a measured value and the true or expected value of a quantity being measured. In scientific research, engineering, and other fields, it’s essential to measure and quantify the error in measurement to ensure the accuracy and reliability of experimental results.

Different types of errors can occur in measurement, including systematic errors and random errors.

- Systematic errors are caused by factors that consistently bias the measurement in one direction, such as a poorly calibrated instrument or incorrect experimental setup.

- Random errors occur due to fluctuations in the measurement process and are unpredictable.

To calculate the error in a measurement, the measured value is subtracted from the true value, and the absolute value of the difference is taken. This is known as the absolute error.

Another way to express error is through relative error, which is the absolute error divided by the true value. This gives the error as a percentage of the true value and is useful for comparing the error between different measurements.

Applications of Accuracy, Precision, and Error Measurement

Accuracy, precision, and error measurement are important concepts in many fields, including science, engineering, and medicine. Here are some specific applications of these concepts:

- Scientific Research: Accuracy and precision are essential in scientific research, where measurements are used to make conclusions and develop theories. Accurate and precise measurements are needed to obtain valid and reliable results.

- Medical Diagnostics: In medical diagnostics, accurate and precise measurements are crucial for making a correct diagnosis and determining the appropriate treatment. Errors in measurements can lead to misdiagnosis, which can have serious consequences for patient health.

- Engineering: In engineering, accuracy and precision are important for ensuring that products and systems work as intended. Errors in measurements can lead to faulty designs or products that don’t meet performance specifications.

- Quality Control: Accuracy and precision are essential in quality control, where measurements are used to ensure that products meet specific quality standards. Errors in measurements can result in defective products or wasted resources.

- Environmental Monitoring: Accuracy and precision are important in environmental monitoring, where measurements are used to monitor air and water quality, climate change, and other environmental factors. Errors in measurements can lead to inaccurate or unreliable data, which can have serious consequences for environmental policy and decision-making.

Recommended Articles:

Principle & Working Of Accelerometer

Acceleration – Introduction, Relationship & Applications

Acceleration Time Graph – Understanding with examples

Acceleration Inclined Plane: Introduction, Laws and Calculating

AC Voltage Resistor – Introduction, Differences and Types

Accuracy refers to how close a measured value is to the true or expected value of a quantity being measured, while precision refers to the degree of agreement among repeated measurements of the same quantity. Error measurement is calculated by taking the absolute value of the difference between the measured and true values of a quantity. The relative error, which is the absolute error divided by the true value, can also be used to express error as a percentage. Sources of error in measurement can include instrument error, environmental factors, human error, and systematic errors such as bias or drift. Accuracy and precision can be improved by using calibrated instruments, taking repeated measurements, identifying and minimizing sources of error, and using statistical analysis to identify and correct outliers. Measurement FAQs

What is the difference between accuracy and precision?

How is error measurement calculated?

What are some sources of error in measurement?

How can accuracy and precision be improved in measurement?